Process Safety Management

Decades of experience combined with the best available current inspection technology can provide the user with the empirical data needed to assess your ammonia system. Various methods used to obtain remaining wall thickness are combined with system age, corrosion rate found to establish calculated remaining life of components and next inspection interval per IVAR specifications.

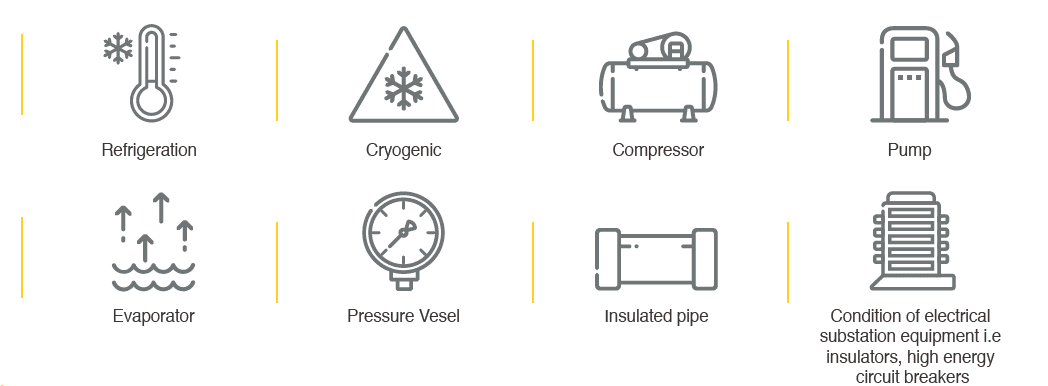

Applications

Inspections are performed in accordance to ANSI/IIAR Standard 6-2019 American National Standard for the Inspection, Testing, and Maintenance of Closed-Circuit Ammonia Refrigeration Systems.. This includes system components such as compressors, pumps, condensers, evaporators, and pressure vessels.

Inspection Methodology

COMPUTERIZED RADIOGRAPHY

The workhorse of the process safety toolbox. This method allows for a visual representation of internal conditions of an area of interest in a jpg format that is easily transmitted for viewing, auditing and archiving. The image is easily calibrated for measurements of components.

ULTRASONIC THICKNESS MEASUREMENT

The best method available to provide the remaining wall of accessible areas under inspection.

INSULATED COMPONENT TESTING - PULSED EDDY CURRENT

A pulsed eddy screening method that provides a percentage loss of ferrous base material. When used with a known component thickness this method will provide remaining wall or wall loss values. Readings are taken through any on-conductive and non-magnetic material

The JANX Difference

Decades of experience combined with the best available current inspection technology can provide the user with the empirical data needed to assess your ammonia system. Various methods used to obtain remaining wall thickness are combined with system age, corrosion rate found to establish calculated remaining life of components and next inspection interval per IIAR standards.

JANX is focused on providing:

- Practical reporting that is adaptable to each client's needs

- Does not require installation of an external program on clients' hardware

- Cross-trained personnel with experience in plant piping, vessels, tanks, transmission piping